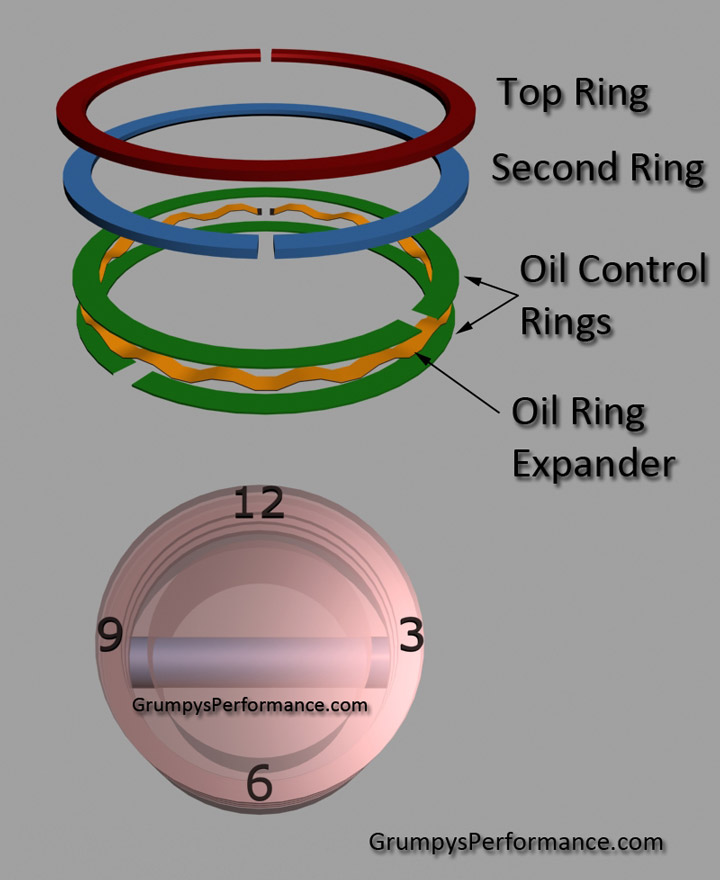

ring and should be installed face UP so that it can be seen when looking at the top of the piston. Installing rings incorrectly will result in poor performance and engine failure can occur. No marking indicates the ring is non-directional and can be installed either way. The laser mark "TOP" does NOT indicate the ring is for the 1st piston.. With the oil ring done, move on to the second ring. This gap should be 90-degrees from the oil ring scrapers, on the exhaust side. Finally, the top ring needs to be 180-degrees from the second ring, on the intake side. With the rings installed, the piston and rod is ready to be installed in the engine. Speedway Motors has a variety of tools.

How to Replace Engine Piston Rings

The Secrets To FileFitting Piston Rings Successfully

How to FileFit and Install Piston Rings

How to install piston rings and not break them. Oil ring explanation POV installation!

Piston ring install orientation Hot Rod Forum

Tips And Tricks For Filing Piston Rings With Real Street Performance

Tips and Tricks For Filing Piston Rings Oliver Racing Parts

How are Piston Rings Made?

Repair Guides Engine Mechanical Pistons And Connecting Rods

How To Install Piston Rings YouTube

Piston Ring Gap How Important Is It And How To Get Them Correct

How to FileFit and Install Piston Rings

Gearhead Piston Rings

Video Explaining How Piston Rings Can Affect Engine Temperature

Proper Piston Ring Gap Is Crucial For Best Engine Performance

Precision Ring Filing A Slick Tool to Set Piston Ring Gap

How to FileFit and Install Piston Rings

Gap Rap How to Measure and Set Piston Ring End Gap OnAllCylinders

How to FileFit and Install Piston Rings

How to FileFit and Install Piston Rings

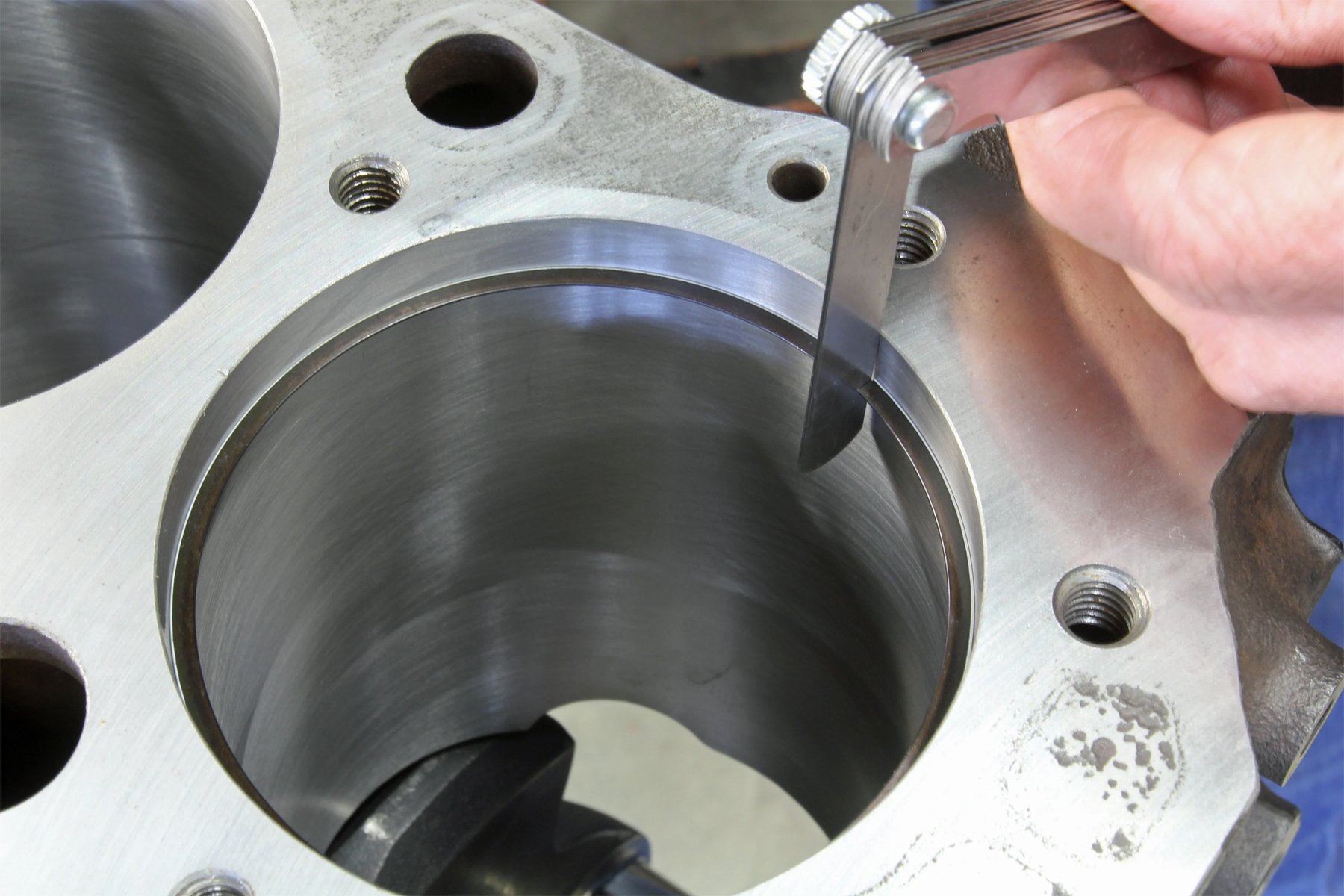

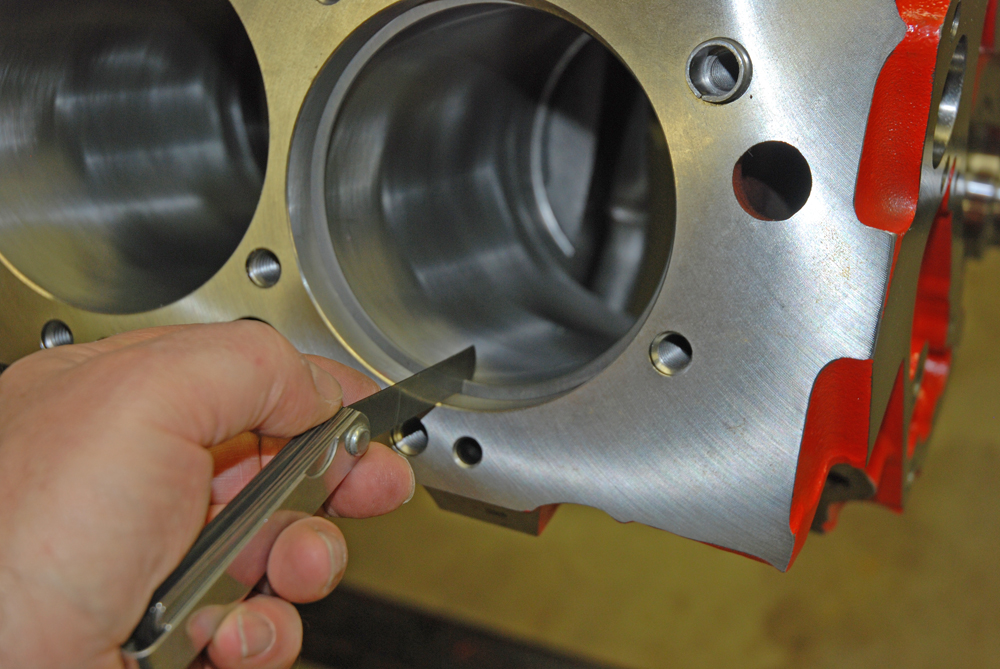

The ring is only square at one distance from the abrasive wheel, so we set the slide .100-inch from the stop, and then adjusted the eccentric with the ring end just touching. See All 10 Photos. Go slowly when filing your rings. File a small amount, check the gap in the respective bore, and then file more as necessary. The idea is to effectively "sneak up" on the gap. Once the gap is set, you should gently deburr the end gap with another small, fine-tooth hand file.